For every job C.T.E. Cablaggi follows an accurate protocol that defines the modality of preparation, production, testing, packaging and order delivery. We review all orders with the client in order to guarantee flexible options. The production team then receives the client’s requests, accompanied by useful instructions to guide them in sourcing materials and executing related procedures (Bill of Materials, Production Cycle, Test Document).

The production cycle is integrated into management software that traces all phases of production. This allows a steady monitoring of progress that the client is informed of in real time. The cabling production cycle always requires a preliminary preparation of the necessary electrical cables, performed in various phases: cutting, sheathing, peeling, branding, and other. These actions are performed automatically by machines, and each phase is constantly tested.

Production includes a seaming phase that is performed automatically or semi-automatically with the many available pieces of equipment.

Seaming is a crucial part of cable production that follows a protocol that includes strict monitoring through specific control systems.

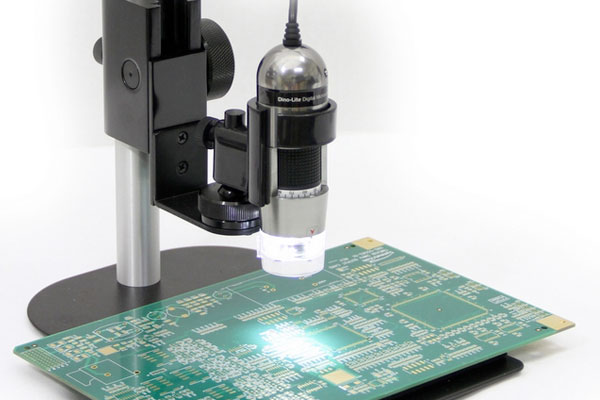

Thanks to the metallographic laboratory and with the help of a personal computer it is possible to verify, photograph and

enlarge the seaming session up to 200 times. We use software that allows us to perform photo measurements and automatically generate a quality report. The electronic dynamometer guarantees

further quality control to ensure the tightness of the terminals.

Thanks to the metallographic laboratory and with the help of a personal computer it is possible to verify, photograph and

enlarge the seaming session up to 200 times. We use software that allows us to perform photo measurements and automatically generate a quality report. The electronic dynamometer guarantees

further quality control to ensure the tightness of the terminals.

The assembly of the cabling and the possibility of a relevant computerized electrical test ensure that the client receives a final cabling devoid of reverse polarity and short circuits.

C.T.E. Cablaggi guarantees respect of the environment by exclusively using materials as defined by the RoHS 2, 2011/65/CE directive.